In today's volatile global trade landscape where logistics costs consume 5-12% of product value, strategic supply chain optimization is no longer optional – it's competitive necessity. At HIF China, we transform logistics from a cost center into a value driver. Discover how our tailored approach helped a Fortune 500 electronics client achieve annual savings exceeding $170,000 USD while enhancing supply chain resilience.

Client Profile & Pain Points

*Anonymous global electronics manufacturer shipping from China to 15+ countries*

Key Challenges:

Ocean Freight Volatility: Unpredictable spot rates and surcharges (BAF/LSS, PSS) inflated costs by 22% quarterly

Reactive Airfreight Overuse: 35% of shipments required premium air transport due to planning gaps

Hidden Destination Costs: Demurrage/detention fees averaged $8,500 monthly from customs delays

Data Blind Spots: No unified visibility into end-to-end logistics spend drivers

The Brief:

*"Reduce total landed costs without compromising our 98% on-time delivery benchmark."*

Our Solution: Precision Logistics Engineering

HIF China deployed a cross-functional SWAT team to implement these data-driven interventions:

1. Diagnostic Deep Dive

Mapped 18-month shipment history across 8 trade lanes

Built cost allocation models identifying 37% savings potential

Benchmarking against industry KPIs using our Global Logistics Intelligence Platform

2. Ocean Freight Optimization

✅ Rate Architecture Overhaul:

Secured protected capacity via Long-Term Contracts (LTCs) on critical Asia-US/West Coast routes

Implemented dynamic procurement blending contract/spot rates

Reduced base rates by 11-18% vs. previous year

✅ Modal Shift Strategy:

Introduced premium ocean services (e.g., SEA-AIR) cutting airfreight usage by 28%

Optimized LCL consolidation achieving 92% container utilization

✅ Surcharge Mitigation:

Pre-emptive BAF/LSS forecasting with hedging recommendations

CGS avoidance routing during peak congestion periods

3. Airfreight Rationalization

Created decision matrix for air vs ocean shipments based on value-density/urgency

Pre-negotiated emergency air corridors with 30-day frozen rates

Implemented demand sensing with client's planning team reducing expedites by 41%

4. Destination Excellence Program

🗂️ Pre-Clearance Protocol:

72-hour advanced documentation submission cutting customs hold time by 1.8 days

Real-time exception management via HIF Control Tower

📊 Partner Governance:

SLAs with penalty clauses for destination agents

Automated detention/demurrage tracking with cost recovery system

5. Digital Transformation

HIF Connect™ TMS implementation providing:

» Live shipment tracking (API-integrated with client's ERP)

» Spend analytics dashboard with savings quantification

» Automated freight audit saving 120 FTE hours monthly

Execution: Collaborative Transformation

Phase 1 (0-90 days): Ocean rate restructuring + pre-clearance rollout

Phase 2 (91-180 days): TMS integration + airfreight controls

Bi-weekly performance reviews with joint KPI scorecards

Knowledge transfer workshops for client's logistics team

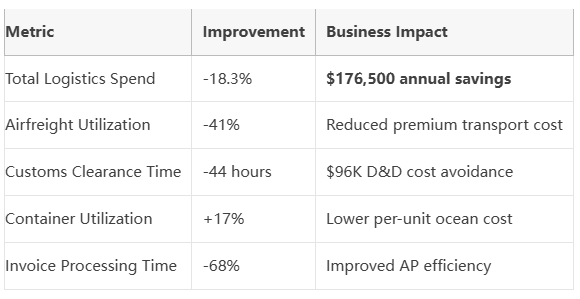

Tangible Results (12-month impact):

Why This Worked: The HIF Difference

Hyper-Personalization: Solutions tailored to client's unique product flow and risk profile

Leverage That Matters: Our $2.8B annual freight volume secured preferential terms

Tech-Enabled Transparency: Real-time cost tracking versus static reporting

Global-Local Execution: 64 in-country partners delivering consistent compliance

Your Turn: Unlock Hidden Savings

"HIF didn't just cut costs – they built us a weatherproof supply chain. Their platform pays for itself in visibility alone."

- Client Logistics Director (anonymized)

Ready for your logistics transformation?

📊 Free Supply Chain Diagnostic:

We'll analyze your last 90 shipments to identify:

Immediate 5-15% cost reduction opportunities

Customized modal optimization roadmap

Destination risk assessment report