In the dynamic Middle East market, logistics efficiency is a critical driver of profitability and competitive advantage. We recently collaborated with a premium electronics importer in the UAE to structurally optimize their supply chain, achieving a 20% reduction in overall operational costs. This case study details our methodology of strategic network redesign, digital clearance integration, and data-driven inventory management to transform logistics from a cost center into a source of resilience and value.

Our initial diagnostic review revealed interconnected inefficiencies, not isolated issues:

Suboptimal Network Design: Reliance on indirect shipping routes with multiple transshipments led to extended and unpredictable transit times.

Reactive Customs Processes: Documentation preparation lagged behind physical shipment movements, consistently generating demurrage, detention, and amendment fees.

Inefficient Inventory Strategy: High safety stock levels were maintained to buffer against supply chain uncertainty, unnecessarily tying up significant working capital.

We implemented a holistic, measurable strategy across the entire supply chain.

Phase 1: Strategic Transportation Network Overhaul

Direct Route Optimization: We designed and secured dedicated direct sailing routes from key Asian ports to Jebel Ali (UAE) and Dammam (KSA), eliminating inefficient transshipment points.

Proactive Capacity Management: Utilizing a mix of long-term agreements and a flexible space pool, we guaranteed over 95% vessel space allocation during peak seasons, converting supply chain reliability into a client advantage.

Phase 2: Digital-First Customs Clearance

Pre-Arrival Clearance Implementation: Our digital platform enabled the submission, pre-check, and compliance validation of key customs documents (like bills of lading and certificates of origin) up to 72 hours before vessel arrival.

On-the-Ground Compliance Support: Our local teams in Dubai and Riyadh provided 24/7 regulatory guidance and rapid issue resolution, reducing average customs discrepancy handling time to under 2 hours.

Phase 3: Demand-Driven Inventory Optimization

Dynamic Safety Stock Modeling: We integrated the client's sales history, market forecasts, and our logistics performance data to build a model that optimally balanced service levels and inventory costs.

Hub-and-Spoke Warehouse Network: Establishing strategic regional distribution centers in the UAE and Saudi Arabia optimized last-mile delivery, cutting local order fulfillment time by 40%.

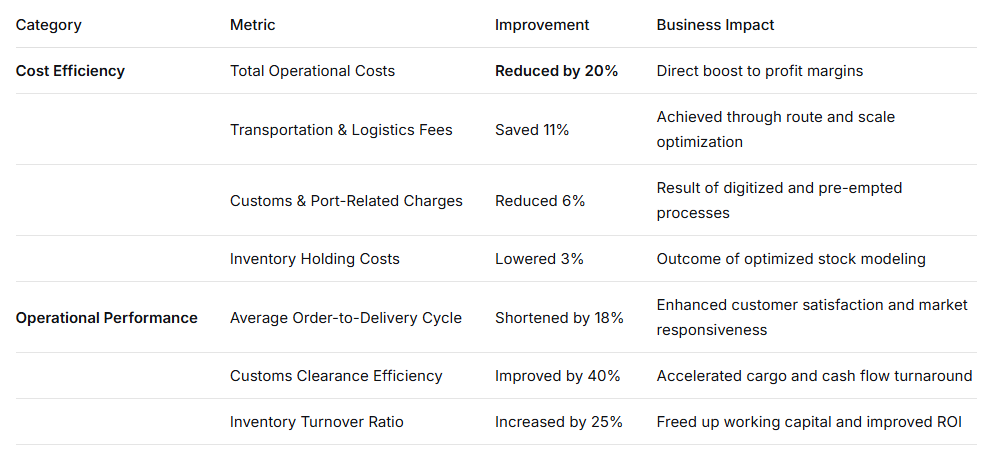

Post-implementation tracking confirmed significant improvements across all key metrics:

Our "strategic inventory positioning" principle delivers exceptional value in sectors like automotive parts, where service speed is critical.

The Client's Challenge: A major Chinese automotive manufacturer's Middle East after-sales service suffered from long lead times (25-30 days) for parts shipped directly from China. To meet service promises, they maintained costly, high-level stock in multiple local warehouses, straining capital efficiency.

Our Designed Solution: We implemented an integrated "Consolidation in China + Hub in Jebel Ali Free Zone (JAFZA) + Regional Distribution across the Middle East" network. Thousands of SKUs were stocked in a bonded logistics center within JAFZA.

Value Created:

Service Transformation: Delivery times for key markets dropped from weeks to under 72 hours, with expedited services available for critical orders.

Cost Restructuring: Consolidating inventory into a single regional hub reduced total regional stock levels by approximately 30% while improving part availability, significantly cutting warehousing and handling expenses.

Cash Flow Advantage: Leveraging the bonded status of JAFZA delayed duty payments until the point of sale, optimizing cash flow.

Business Model Support: This setup enabled a strategic shift from mere parts export to establishing localized, rapid-response service capabilities in the region.

Our expertise is built on deep regional insight and forward-looking execution:

Logistics as a Strategic Asset: A robust supply chain is a competitive moat that enables market growth, ensures customer satisfaction, and supports premium branding.

Compliance as an Enabler: Proactively embedding customs compliance into logistics planning is essential for mitigating risk and accelerating cycle times in the Middle East.

Visibility Equals Control: Our end-to-end digital visibility platform provides real-time shipment tracking, transforming the supply chain into a transparent, manageable process.

Building for Resilience: We develop tailored contingency plans for seasonal peaks like Ramadan and national holidays, ensuring consistent, uninterrupted operations for our clients.